ECODEPUR

LIGHT LIQUID SEPARATOR

LIGHT LIQUID SEPARATOR / ECODEPUR® DEPUROIL®

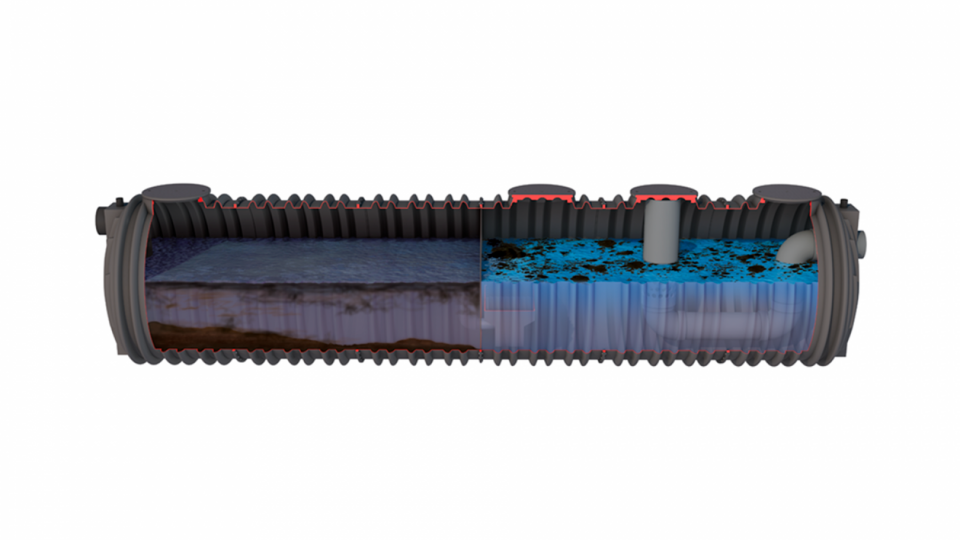

ECODEPUR® DEPUROIL® is Light Liquid Separator destined to clean water polluted with light free floating liquids such as engine oils, gas, oil etc. Separators has CE marking, fulfilling all the requisites of the European Standard EN 858-1:2002. Standard models up to 15l/s.

LIGHT LIQUID SEPARATOR / ECODEPUR® OILTECH®

ECODEPUR® DEPUROIL® is Light Liquid Separator destined to clean water polluted with light free floating liquids such as engine oils, gas, oil etc. Separators has CE marking, fulfilling all the requisites of the European Standard EN 858-1:2002. Standard models up to 15l/s.

LIGHT LIQUID SEPARATOR / ECODEPUR TECHNOIL

ECODEPUR® TECHNOIL® is Light Liquid Separator destined to clean water polluted with light free floating liquids such as engine oils, gas, oil etc. Separators has CE marking, in accordance with the legal obligations that stems from the entry into force of the Regulation (UE) N.º 305/2011 of Construction Products, fulfilling all the requisites of the European Standard EN 858-1:2002.

LIGHT LIQUID SEPARATOR / DEPUROIL® BY-PASS

Equipment destined to clean water polluted with light free floating liquids such as engine oils, gas, oil etc. with built-in bypass Made in polyethylene, buried installation and without energetic consumption. Nominal sizes (l/s) greater than 15 l/s, available on request.

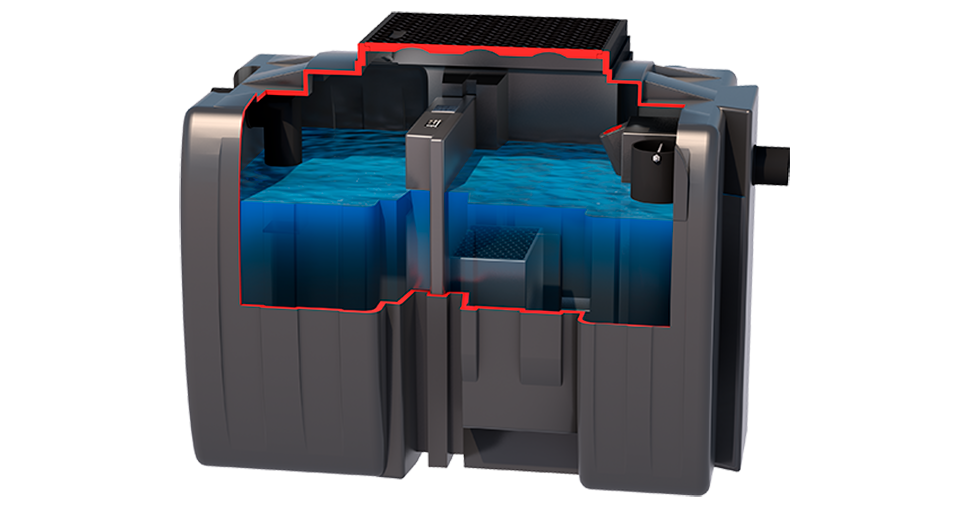

LIGHT LIQUID SEPARATOR / ECODEPUR® DEPUROIL® EE

ECODEPUR® DEPUROIL® EE is Light Liquid Separator destined to clean water polluted with light free floating liquids such as engine oils, gas, oil etc, Class 1 in according of EN 858, with double coalescent cell and automatic closure device.

WASH WATER RECYCLR SYSTEM

DEPURWASH system allows treatment of effluents generated in vehicles and machinery washing operations, being applied downstream S-IPlines (Sludge Trap / Oil Separator / Sample collection box) according to EN 858 -1 / 2, adjusting the treated water quality for reuse during the stages of pre-wash and wash.

The system reduces up to 90% water consumption in washing operations, resulting not only in an effective contribution to the preservationof resource “water” but also a worthwhile investment with economic return in the short term. The excess effluent meets the discharge limits imposed by current legislation regarding the parameters COD, BOD5, TSS, Grease & Oils and Total Hydrocarbons and can be directly discharged in natural areas (water / soil).

SLUDGE TRAP

SLUDGE TRAP | ECODEPUR® DS

The Sludge Traps ECODEPUR® DS are mainly used to remove precipitable substances from waste water.

LAMELLAR SLUDGE TRAP | ECODEPUR® DEKTECH

The Lamellar Sludge Trap ECODEPUR® DEKTECH are mainly used to remove precipitable substances from water polluted with light free floating liquids such as engine oils, gas, before a Light Liquid Separator.

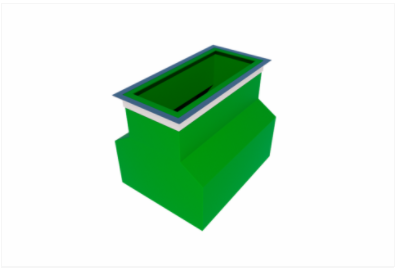

BASE SUMP TANK

ECODEPUR® ECO BST and ECO BST PLUS are Base Sump Tanks, completely tight, used directly in Oil tanks Manholes. Provides a direct access to equipment’s, such as pumps, and offer a clean and dry area. They serve as a liquid tight isolation chamber, preventing ground water from entering and any leaking product from escaping into the environment.

The raw material used (Linear Polyethylene) was tested by an independent entity, guaranteeing high mechanical resistance and corrosion protection.

The equipment production under controlled conditions, the use of quality raw materials and the finished product inspection, in accordance with the demands of ISO Standard 9001, guarantee the final product quality.

ECODEPUR® Eco BST and Eco BST PLUS have 5 Year Guarantee against any manufacturing defects

DISPENSER SUMP

ECODEPUR® DS are Dispenser Sump, installed beneath fuel dispensers to provide secondary containment of dispenser plumbing and emergency shear valves.

They serve as a liquid tight isolation chamber, protecting pumps and their connections.

ECODEPUR® DS range includes Five sump sizes and Two different metallic structure, with outside or inside lip (to use and adjust in different dispensers) and Stabilizer bars. (The raw material used (Linear Polyethylene) was tested by an independent entity, guaranteeing high mechanical resistance and corrosion protection.

The equipment production under controlled conditions, the use of quality raw materials and the finished product inspection, in accordance with the demands of ISO Standard 9001:2008, guarantee the final product quality.

ECODEPUR® DS has 5 Year Guarantee against any manufacturing defects.